Nonwoven fabric is a fabric-like material made from staple fibre (short) and long fibres (continuous long), bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted.[1] Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foamAll the manufacturers, suppliers, distributors, intermediaries, and customers involved in the Nonwovens industry globally are studied.

Meltblown is a conventional fabrication method of micro- and nanofibers where a polymer melt is extruded through small nozzles surrounded by high speed blowing gas. The randomly deposited fibers form a nonwoven sheet product applicable for filtration, sorbents, apparels, and drug delivery systems. The substantial benefits of melt blowing are simplicity, high specific productivity, and solvent-free operation. Choosing an appropriate combination of polymers with optimized rheological and surface properties, scientists have been able to produce melt-blown fibers with an average diameter as small as 36 nm.

Spunbond, also called Spunlaid, nonwovens are made in one continuous process. Fibers are spun and then directly dispersed into a web by deflectors or can be directed with air streams. This technique leads to faster belt speeds, and cheaper costs. Several variants of this concept are available, such as the REICOFIL machinery.[6] PP spunbonds run faster and at lower temperatures than PET spunbonds, mostly due to the difference in melting points

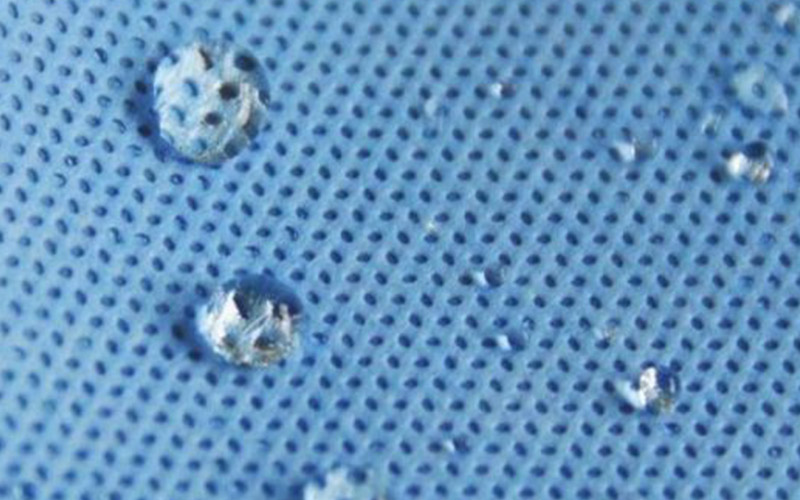

SMS Spunbond has been combined with melt-blown nonwovens, conforming them into a layered product called SMS (spun-melt-spun). Melt-blown nonwovens have extremely fine fiber diameters but are not strong fabrics. SMS fabrics, made completely from PP are water-repellent and fine enough to serve as disposable fabrics. Melt-blown is often used as filter media, being able to capture very fine particles. Spunlaid is bonded by either resin or thermally. Regarding the bonding of Spunlaid, Rieter has launched a new generation of nonwovens called Spunjet. In fact, Spunjet is the bonding of the Spunlaid filaments thanks to the hydroentanglement.

SSS nonwoven pure polypropylene as raw material. After three S-touches, they are simultaneously spun into a net and hot rolled. Better uniformity and flexibility than S/SS. The main application of SSS non-woven fabric: SSS non-woven fabric is applied to the sanitary material: diapers, hydrophilic layers of sanitary napkins, composite base films, and the like. SSS nonwoven fabrics are used in medical treatments: surgical gowns, protective clothing, hats, masks, sauna suits, tapes, etc. SSS non-woven fabric is used for protection: shed cloth, plant pest control, cold protection, sunscreen coverage, etc. SSS nonwoven fabrics are used in packaging: suits, shopping bags, gift bags, hanging bags, sleeping bags, dust covers, grain packaging, shoe leather, bags, mattresses, sofa linings, storage boxes, and automobiles, home decoration, waterproof, filter coils, roadbeds, breakwaters, etc.